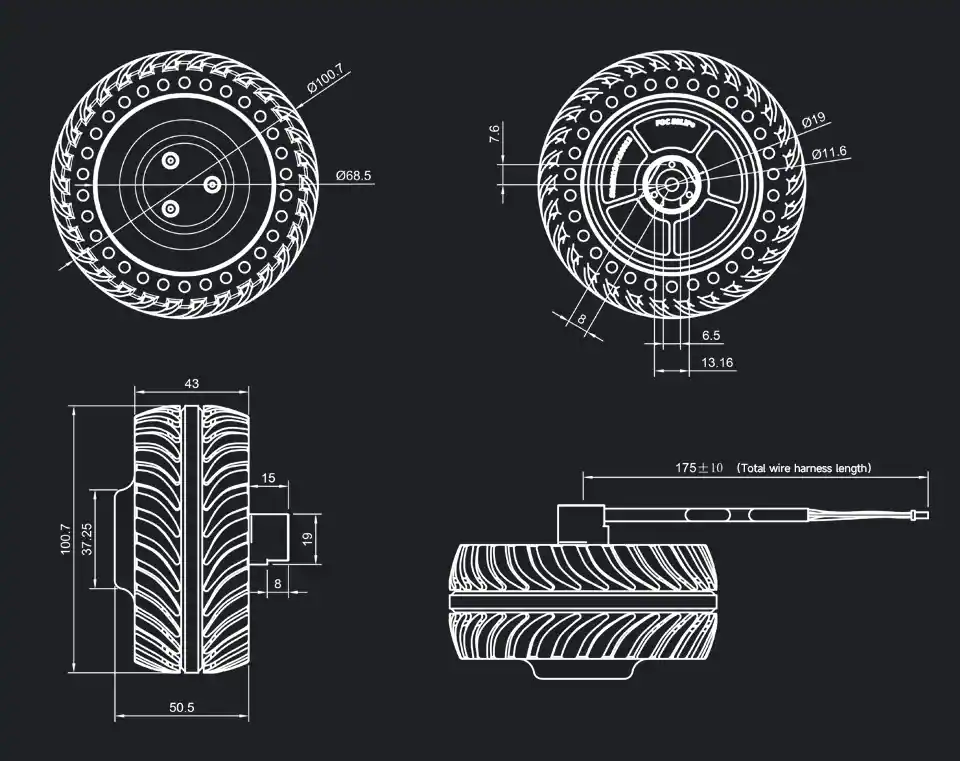

Compact All-In-One Hub Motor for EVs, Robotics, and Automation Systems

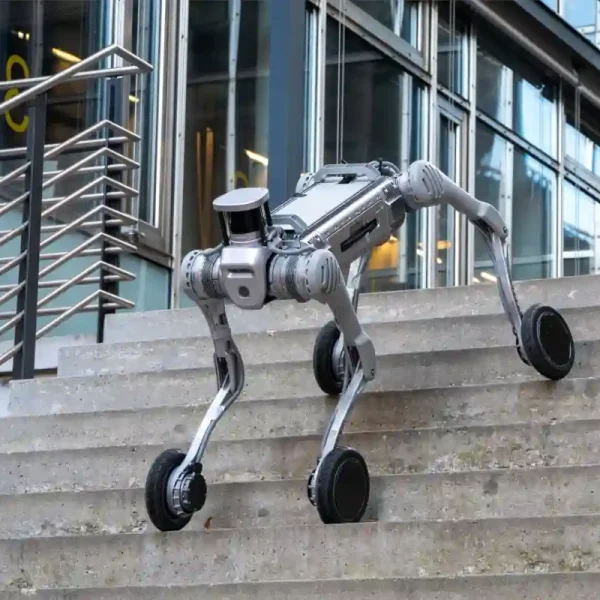

Based on the integrated development concept, ZHDD-115 is a high-reliability Permanent Magnet Synchronous Motor (PMSM) integrating an outer rotor brushless motor, encoder, and servo. With a compact structure, it is easy to install and can be operated stably. As it is small while with high torque, it can be applied for the following advanced robot projects such as robot joints, small AGV drive wheels, balance car drive wheels, and the development of vehicle platforms.

By optimizing the number of poles and slots, slot type, air gap, permanent magnet material, etc., it is ensured that the motor has greater torque output and smaller torque fluctuations, and realizes direct drive with low speed and high torque, providing users with high-performance direct-drive application solutions.

As the drive for the motor adopts the Field Oriented Control (FOC) algorithm and works with the built-in high-precision sensor, the motor can be precisely controlled with lower noise. The driver also has a complete and reliable OBD (Onboard diagnostics) monitoring mechanism and protection functions for the motor to ensure safe and reliable motor operation. 120N.m

Low Speed & High Torque Low Noise Direct Drive Servo Motor All-In-One Design Hub Motor

High-torque Permanent Magnet Synchronous Motor (PMSM) with integrated encoder and servo. It offers stable, precise control for robotics, AGV wheels, and balance cars, using Field Oriented Control (FOC) and onboard diagnostics for reliability.

- Please confirm whether the operating voltage is specified in this article (5S LiPo, 5s lithium battery (five lithium batteries in series) voltage range) before use.

- Please make sure the motor is used under the specified environment range (-20℃~45℃), the motor over-temperature protection threshold is 80°C, and the protection is released when the temperature is lower than 75°C.

- Please avoid immersing the motor in water, otherwise, it may cause abnormal operation or damage to the engine.

- Please ensure that the wiring is correct and stable before use to avoid poor contact.

- Please refer to the installation instructions before using the motor to ensure that the motor is installed correctly and firmly.

- Please refer to the installation instructions before using the motor to ensure that the external output part of the motor is installed correctly and firmly.

- Please avoid damage to the wire during use, otherwise, it may cause abnormal operation or damage to the motor.

- Do not touch the rotating part of the motor during use to avoid injury.

- When the motor outputs high torque, it will generate heat. Do not touch the motor to avoid burns.

- Do not disassemble the motor without permission, otherwise, it may cause abnormal operation or damage to the motor, and may bring safety hazards.

Feature

- Ultra-low noise

- High precision and zero-backlash

- Fast response, direct drive without delay

- Integrated motor and driver, compact structure and high integration

- Support RS485 communication mode

- Motor feedback information such as position, speed, current, error code, etc. can be obtained through communication.

- With Hall position detection, over-current protection, etc.

- Support electric brake

- No drive mechanical friction, drive efficiency close to 100%

Parameter

- No-load speed: 200±10rpm No-load current: ≦0.25A

- Rated speed: 115rpm Rated torque: 0.96Nm

- Rated current: 1.5A Maximum efficiency: ≥60%

- Locked-rotor torque: 2.0Nm Locked-rotor current: ≦2.7A

- Rated voltage: 18V DC (5S LiPo) Voltage range: 12-24V DC

- Torque constant: 0.75Nm/A Speed constant: 11.1rpm/V

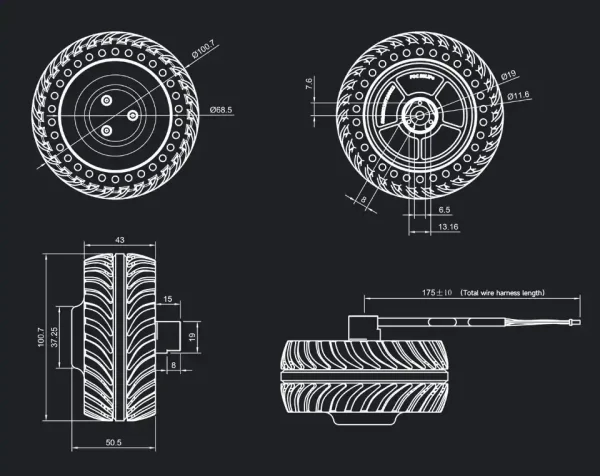

- Operating temperature: -20~45℃ Total weight: 765±15g

- Encoder resolution: 4096 Relative accuracy: 1024

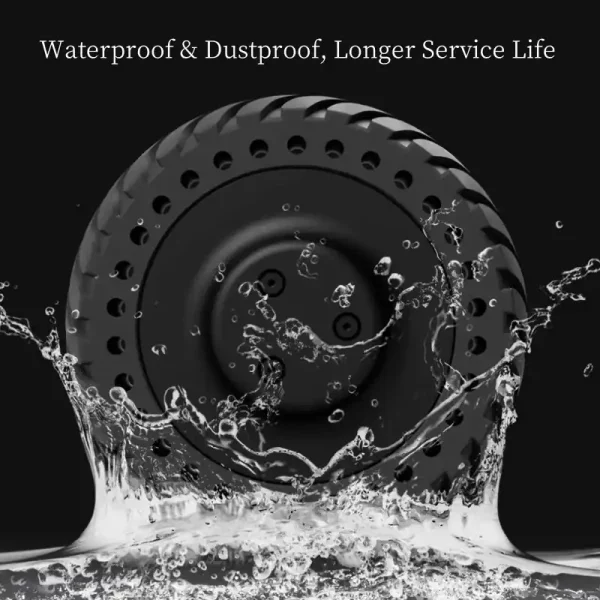

- Noise level: ≦50dB Degree of protection: IP54

- Single-wheel load: 10kg

| Weight | 1 kg |

|---|---|

| Dimensions | 14 × 14 × 10 mm |

Reviews

There are no reviews yet.