In recent years, robotics has become an indispensable part of modern industry and daily life. From manufacturing to healthcare, robots play a crucial role in enhancing efficiency, precision, and safety. At the core of these robots, micro motors and servo motors play a vital role. With advancements in technology and cost reductions, these motors are driving a wave of low-cost innovation, making advanced robotics more accessible to businesses and individuals.

Micro Motors: Small Yet Powerful Powerhouses

Micro motors are small electric motors typically used to drive small devices or robots. They are favored for their compact size and efficient energy conversion.

Types of Micro Motors

- Brushless DC Motors (BLDC):

Brushless DC motors are popular in micro-robotic applications due to their high efficiency, long lifespan, and low maintenance needs. Unlike traditional brushed motors, BLDC motors do not have brushes, reducing friction and wear. - Brushed DC Motors:

Although brushed motors are less efficient and have shorter lifespans than brushless motors, their simple control and low cost make them attractive for some budget-conscious applications. - Stepper Motors:

Stepper motors achieve precise motion control through step-by-step rotation. They are commonly used in applications requiring high precision positioning, such as 3D printers and small CNC machines.

Applications of Micro Motors

- Consumer Electronics:

Micro motors are widely used in smartphones, drones, cameras, and other devices. For example, the vibration motor in smartphones is a type of micro motor that provides haptic feedback. - Medical Devices:

In the medical field, micro motors drive surgical robots, automatic injectors, and portable medical devices. These devices require high reliability and precision, which micro motors can deliver. - Industrial Automation:

Micro motors are used in industrial automation for small robotic arms, conveyor belts, and precision machining equipment. They provide powerful performance in compact spaces, making industrial equipment more efficient and compact.

Servo Motors: Keys to Precise Control

Servo motors are motors equipped with a feedback control system, capable of achieving high-precision position, speed, and acceleration control. They are commonly used in high-end applications requiring precise motion control.

Working Principle of Servo Motors

The core components of a servo motor include the motor body, encoder, and controller. The encoder detects the motor’s actual position or speed and feeds this information back to the controller. The controller adjusts the motor’s output based on the feedback signal to achieve precise motion control.

Types of Servo Motors

- AC Servo Motors:

AC servo motors offer high efficiency and power density, suitable for high-performance applications. They are typically used in industrial robots, CNC machines, and automated production lines. - DC Servo Motors:

DC servo motors are widely used in robotics, automatic doors, and precision instruments due to their simple control characteristics and quick response.

Applications of Servo Motors

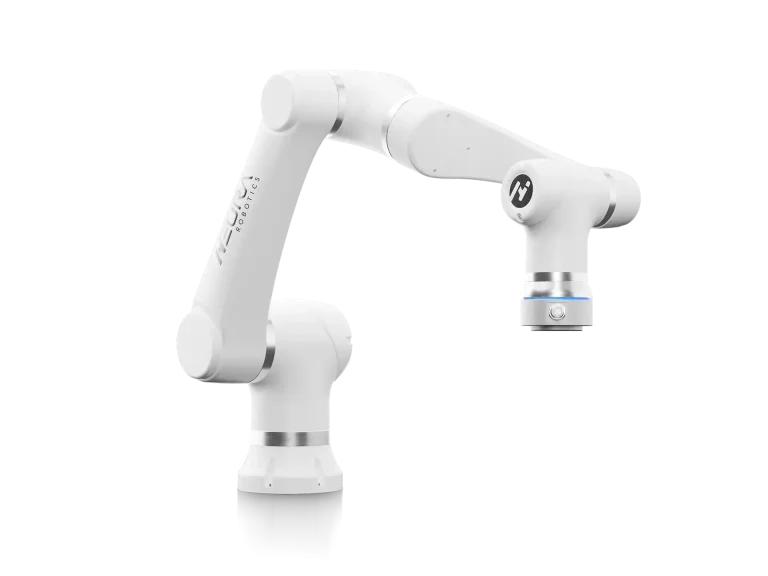

- Industrial Robots:

Servo motors are extensively used in industrial robots. They provide high-precision position control, enabling robots to perform complex tasks such as welding, assembly, and material handling. - CNC Machines:

CNC machines require precise motion control to ensure machining accuracy. Servo motors precisely control the position and speed of the tool, ensuring high-quality and efficient machining processes. - Automated Production Lines:

In automated production lines, servo motors drive conveyor belts, robotic arms, and other equipment to achieve efficient and precise production processes.

Low-Cost Innovation in Micro Motors and Servo Motors

With technological advancements, the cost of micro motors and servo motors is gradually decreasing, making advanced technologies more affordable for businesses and individuals.

Advances in Manufacturing Processes

- Material Science Advances:

The development and application of new materials, such as high-performance magnetic materials and lightweight structural materials, have improved motor performance while significantly reducing production costs. - Automated Production:

Advanced automated production technologies, such as robotic assembly and intelligent inspection, have significantly increased motor production efficiency, reducing manufacturing costs.

Design Optimization

- Modular Design:

Modular design makes motor production and maintenance more convenient and low-cost. By using standardized components, production processes can be simplified, and inventory costs can be reduced. - Integrated Circuits:

Advanced integrated circuit technology makes motor controllers more compact and efficient. The use of integrated circuits not only enhances motor performance but also lowers the overall system cost.

Expanding Market Scale

- Growing Demand:

As robotics technology becomes widespread across various fields, the demand for micro motors and servo motors has increased significantly. Economies of scale have reduced the production cost per motor. - Global Supply Chains:

The development of global supply chains has made the procurement of key components more efficient and low-cost. International market competition also drives manufacturers to continuously optimize production processes and reduce prices.

Innovative Applications Enabled by Low-Cost Motors

Education and Research

Low-cost micro motors and servo motors enable educational institutions and research units to conduct more experiments and projects. For example, students can use these motors to create robot prototypes, learning motor control and robotics programming.

Automation for Small and Medium Enterprises

Previously, high motor costs limited the automation processes of small and medium enterprises (SMEs). Now, low-cost micro motors and servo motors allow SMEs to afford automation equipment, improving production efficiency and product quality.

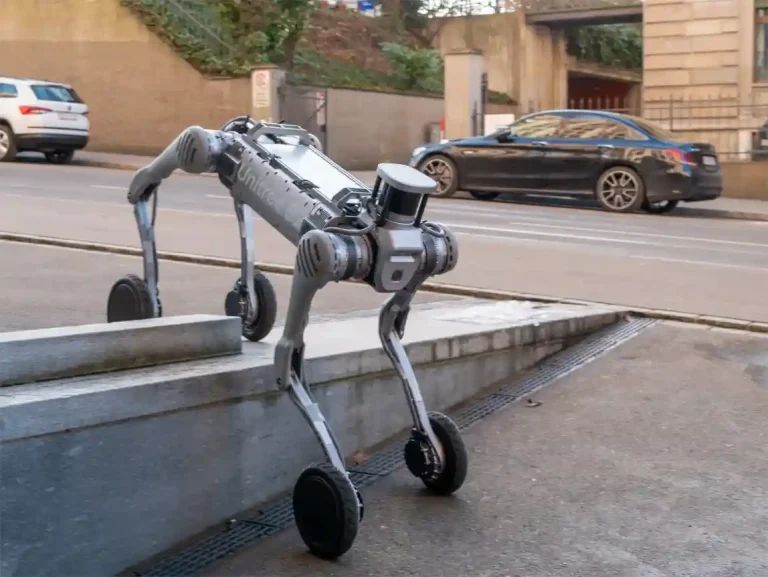

Consumer Robotics

The proliferation of low-cost motors has made consumer-grade robots, such as home cleaning robots, entertainment robots, and smart toys, more widespread. These robots not only enhance people’s quality of life but also promote the adoption and application of robotics technology.

Future Prospects

As technology continues to advance, the performance of micro motors and servo motors will keep improving, and costs will further decrease. Here are some potential development directions:

- Smart Motors:

Integrating artificial intelligence and sensor technology into motors can make them adapt to environmental and task requirements, enhancing system intelligence. - Wireless Control:

Wireless technology can enable remote control and monitoring of motors, greatly increasing system flexibility and convenience. - Energy Efficiency and Environmental Friendliness:

Developing more efficient and eco-friendly motor technologies can reduce energy consumption and environmental impact.

Conclusion

Micro motors and servo motors play a crucial role in robotics technology. With advancements in manufacturing processes, design optimization, and market expansion, the cost of these motors continues to decrease, driving a wave of low-cost innovation. This makes advanced robotics technology more affordable for businesses and individuals, opening up numerous new application scenarios. In the future, as technology continues to develop, micro motors and servo motors will demonstrate their powerful potential in more fields, bringing more convenience and innovation to humanity.